Machining processes

Turning

Finest turning, drilling and countersinking operations.

Milling

Conventional milling machine for tooling construction and for the finest drillings.

Grinding

Special bevel or contour grinding, also for cup-piercing.

Centerless external cylindrical grindings

Production of defined external contours while retaining the internal diameter.

Forming

Hammering & Rotary swaging

The completely computer- and SPS-controlled process for rotationally symmetrical tube reduction is carried out by pressure forming using hammers in the rotary swaging process.

The cold workpiece, previously annealed under inert gas, is fed axially to the oscillating tools and cold formed first in the inlet cone and then in the calibration section. The use of special internal tools, so-called mandrels, in the hammering process produces precise and smooth internal surfaces.

Using feed swaging, we process tubes with outside diameters of Ø8 mm downwards and, thanks to the latest technology, achieve inside diameters of Ø0.1 mm with high surface quality and narrow tolerances.

At the same time, the material is work-hardened by hammering, which increases the strength of the machined tube almost uniformly over the entire cross-section.

Our experience in hammering enables us to achieve an excellent internal surface finish both in the cylindrical part and in the cone of the tubes.

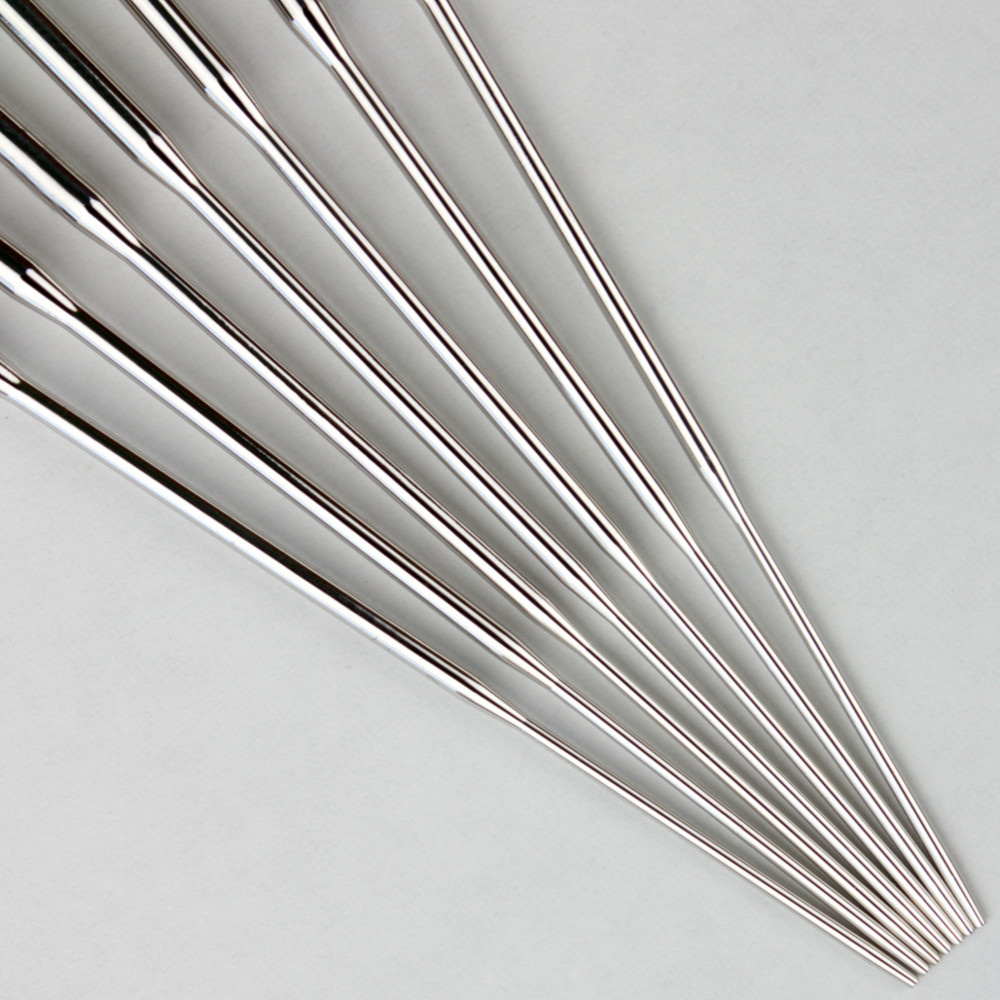

Cannula, three times reduced

Bending

Thanks to our own in-house tooling construction, we are able to implement bends and windings quickly and precisely.

Expanding / flattening of pipes

Expansions of pipes, for example for pipe connections, are implemented in various processes using specially manufactured in-house tools.