Hollow stainless steel needles used for analytical and/or diagnostic purposes are sometimes required to pierce rubber, plastic or aluminum container closures (cup piercing) when taking samples or reagents.

When piercing the septum, friction occurs which must be overcome. Due to this frictional resistance, greater forces act on the needle and robot arm.

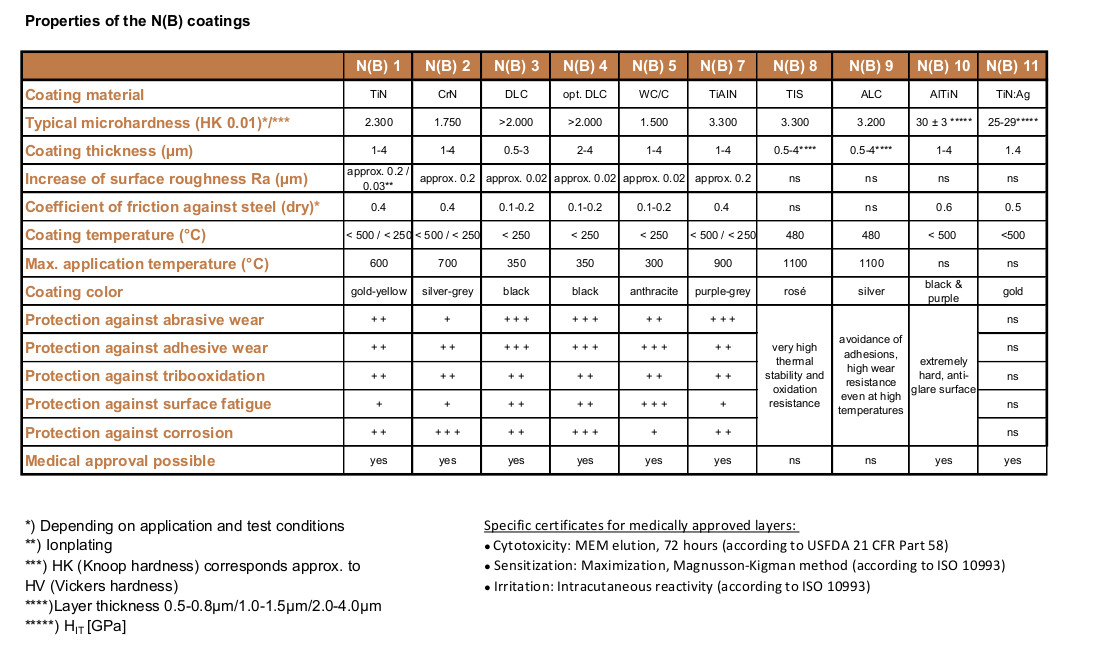

Significant improvements can be expected from coatings on the outer surface of the needle with abrasion-resistant hard material coatings such as gold-colored titanium nitride (TiN). Other possible hard coatings are TiAIN and diamond-like carbon (DLC). All hard material coatings are deposited under vacuum using plasma-assisted PVD technology.

Coatable substrates

External surfaces of cannulas.

Dimensions

OD Ø0.5 – Ø4 mm, length up to 300 mm

Properties of hard material coatings

Application examples

Pipetting needles with various hard material coatings